Unilever soup move boosts aseptic in Netherlands

Aseptic packaging has taken a leap forward in the Netherlands, with Unilever launching its Unox brand into aseptic cartons for the first time in partnership with SIG Combibloc.

Unilever claims the move sets new trends in terms of quality. Soup manufacturers in the Netherlands had until now largely delivered ready-to-eat soups in food metal cans and pouches, it said.

Aseptic processing is known for its gentler processing methods, which potentially delivers better taste and texture. “In aseptic carton packs foods are hygienically and securely protected from light, air and external odours,” a spokeswoman for SIG C ombibloc told FoodProductionDaily.com.

“The flavours, colours and nutrients, and the vitamins and aromas of the food products are retained. With their original seal left intact, food products packaged in carton packs can be stored for up to three years even outside the cold chain or refrigerator, and still retain their high quality.”

Trends

The development was driven by industry and consumer trends, she added. “What is needed are modern packaging solutions that provide optimal protection for the foods they contain, offer flexibility, are convenient to use, have a superlative environmental profile – and, at the end of the day, are cost-effective as well.”

To fill the products, Unilever invested in a food filling machine from SIG Combibloc that makes it possible to put food containing extra large pieces into carton packs.

Manufacturers receive the packaging materials for their products from SIG Combibloc as pre-fabricated blanks, printed with the required design, precisely marked with fold lines and pre-sealed as sleeves.

The filling process

These sleeves are opened into shape on SIG Combibloc’s filling machines and sealed at the base. The soups, which are sterilised using the ultra high temperature (UHT) process, are filled into C ombiblocStandard 1,000ml carton packs that are open at the top.

Only when the filling process is completed is the packaging sealed above the filling level, not through the product. This prevents parts of the product from being caught in the sealed seam and ensures gentle and safe filling, according to SIG C ombibloc.

The technology enables processors to aseptically fill packs with food pieces up to 40mm in diameter and the portion of particulates can be up to 50%.

Unilever said it believed the approach would attract new consumers, especially soup was a growing category.

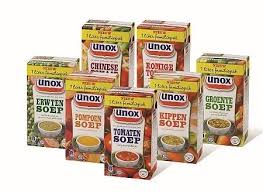

The carton pack soups are available in tomato, chicken, pea, cream of tomato, Chinese tomato, vegetable and pumpkin varieties.