The Role of High Pressure Processing in Beverage Innovation

By Errol Raghubeer, Ph.D., Vice President Microbiology & Food Technology, Avure Technologies

As consumers trade in their traditional carbonated soft drinks and fructose-laden juices for alternative beverages that are “healthy,” “fresh” and “all natural,” the global beverage industry has responded with countless innovative products – and increased competition in this rapidly growing market. It’s not surprising that for beverage manufacturers, one of the top three expected key changes in business structure is to “expand in emerging markets.”*

This demand for the convenience and health benefits of fresh all-natural juices and other beverages comes hand in hand with consumer expectations that these products be safe and maintain their sensory properties.

Pathogen Elimination, Nutrition and Flavor Retention, Shelf-Life Extension

High Pressure Processing (HPP), a mainstream pre- or post-package process, maintains the fresh taste and nutrition properties of fresh juice. With HPP, fresh juice product is subjected to very high pressures (up to 87,000 psi), for short exposure times to achieve the inactivation of foodborne pathogens such as Salmonella, E. coli O157H:7, Listeria monocytogenes and Cryptosporidium parvum, and spoilage organisms, including yeast and mold.

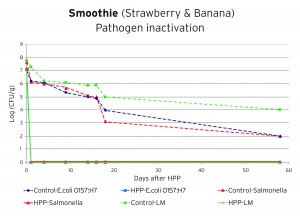

The results of published studies and those by Avure Technologies confirmed that the use of HPP on fresh juice, and other beverages made from fruit-vegetable blends, fruit and yoghurt combinations and smoothies (Figure 1), nut milks and other blends meet the FDA 5-log pathogen reduction requirement as well as those of other countries. In the beverage industry HPP is a post lethality treatment in the final package that can be incorporated as a critical control point (CCP) in a HACCP program to ensure food safety.

Figure 1

Heat treatment and other processes have adverse effects on taste, color, and significantly affect vitamins and other bioactive compounds. One of the biggest advantages of HPP in the beverage industry is that the nutrients remain largely unaffected and most sensory properties remain unchanged. Additionally, beverage manufacturers using HPP can offer natural products to their customers as there is no need for preservatives to control pathogens and spoilage microorganisms.

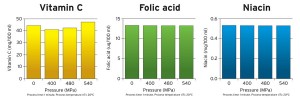

Beyond flavor profile and retention of nutritional value, such as Vitamin C, folic acid, niacin, and antioxidant content, (Figure 2), HPP can extend refrigerated shelf life to several months depending on product formulation and packaging. Longer shelf life translates to increased distribution opportunities, reduced returns, greater tolerance to cool chain abuse, and more efficient production scheduling.

Figure 2

Retail Opportunities For Fresh and Handcrafted Beverages With HPP

Shelf-life extension being offered by HPP is causing retailers, like Whole Foods, to take delivery of natural and nutritious beverage products created by smaller, boutique beverage purveyors that address their shelf-life needs as well as those of their customers. The profit margins to be achieved with high value beverage products are welcomed by larger retailers fighting for the beverage dollars being spent in juice and smoothie shops on street corners in nearly any locale today.

Take the example of Vegesentials, a U.K. company founded by Managing Directors Patience and Andrew Mugadu, to blend and market their line of fresh, all natural, super-vegetable juices and smoothies. Scaling up to meet retail demands meant facing the challenge of how to make a commercially viable product without losing fresh, homemade flavor and inherent nutrition.

With HPP, Vegesentials juices deliver exceptional fresh taste with complete nutrient retention that stay fresh longer – in some cases for as much as 30 days – and have been picked up by Whole Foods and other retailers, something that would not otherwise have been possible.

To learn more about Avure High Pressure Processing Solutions, go to www.avure.com/food, watch “The Science of HPP and Beverage Innovation” (info.avure.com/foodbevbiz), or call +1.614.891.2732.

To learn more about Avure High Pressure Processing Solutions, go to www.avure.com/food, watch “The Science of HPP and Beverage Innovation” (info.avure.com/foodbevbiz), or call +1.614.891.2732.

* Source: Global Beverage Survey 2013-2014: Market Trends, Buyer Spend and Procurement Strategies in the Global Beverage Industry