Successful Protein Processing For Different Requirements

The global protein ingredients market was valued at $25.62 billion in 2016 and is expected to see CAGR growth of more than 7 percent until 2025.1 We speak to Christian Diener from the Sales department at Ruland Engineering & Consulting to find out what is involved in protein processing.

Q: What are the main challenges associated with protein processing?

CD: Demand for protein is at an all-time high and it’s still growing. Against a backdrop of dwindling global resources, this means that being able to extract the maximum amount of this valuable nutrient from the source material is vital. It is also crucial to be able to achieve this in a sustainable way – not only from the point of view of being better for the environment, but also because consumers are now looking more favourably at companies that have sustainable principles.

The fact that the food and drinks industries are now using an increasing number of protein sources also brings challenges. Since each of these has its own special biological make up and characteristics, a ‘one size fits all’ solution is not appropriate for protein processing. In order to achieve the best results and an optimum yield, it is essential that the equipment is tailored to the specific raw ingredients, and this definitely requires specialist knowledge, expertise and experience.

Q: Are there any limits to the raw materials that proteins can be extracted from?

CD: Advances in technology mean that protein can now be extracted from all sorts of raw materials. Alongside traditional animal, fish and plant sources like soy, protein is being gleaned from substances as diverse as microalgae, cereal crops and crickets.

Q: What steps are involved in the protein processing procedure?

CD: Processing generally starts with the separation of distinct components from a mixture of water, protein and fats, followed by the removal of coarse solids and fats using decanters and separators. After passing through a centrifuge, the remaining turbid elements and residual fats are separated, leaving a mixture of protein and water. The length of the amino acid chains that are naturally present in the protein coupled with process parameters such as temperature and pH mean that particular expertise is required here. All equipment has to be set up to handle the specific attributes of each type of protein, and the quality of the outcome is highly dependent on the use of membranes with appropriate pore diameters and suitable filters. It’s crucial to get this initial step right because if you don’t, you risk loss of product and an inferior result.

For long-chain proteins, in most cases, conventional filtration systems, such as diatomaceous earth, are used because the proteins are too long to pass through fine-pored membranes, which would become clogged. For short-chain and hydrolysed proteins, on the other hand, fine-pored membrane technology is best as it helps to remove the remaining turbid elements from the protein mixture. In fact, this method produces significantly better results in terms of turbidity (NTU-value) than standard filters.

Q: What happens to the protein mixture after filtration?

CD: The next steps are desalination and concentration. Appropriate membrane technology will once again be used here, in many cases combined with an evaporation system.

Only partial desalination is required in some cases, and specialist ion exchangers and membranes are used to achieve this. Ultrafiltration and nanofiltration membranes remove mono- and polyvalent salts as well as bitter compounds and other flavours and odourants. An additional diafiltration stage can wash even more salt out of the product.

Diafiltration combines the features of dialysis and ultrafiltration. During this process, a solvent is continuously added to the pre-concentrated protein solution until the old solvent has been completely replaced via the membrane. The volume of the suspension remains unchanged.

Depending on the pre-treatment methods used, the main process is then carried out in either one or two steps. If the proteins are highly hydrolysed and of a short chain length, the solution can be concentrated using membranes up to the required level and then spray dried. For long-chain proteins, the final concentration can be reached by means of an additional evaporation stage.

Q: What advantages does the use of membranes as well as evaporation equipment bring?

CD: Using a combination of membranes and evaporation equipment for the processing of long-chain proteins offers the advantage of allowing the processor to choose the optimal transition point. Not only does this relieve the membranes, but it also allows a single or multi-stage evaporation plant to be downsized. This results in optimal allocation of resources at the same time as achieving the best quality output.

Q: When a certain type of protein is required, how can the extraction process be tailored to deliver exactly what is needed?

CD: In order to obtain a protein hydrolysate with a clearly defined range of chain lengths, protein fragments need to be separated according to their molecular size. A multi-stage filtering process involves initial filtering of large, long-chained particles through an open membrane, followed by the separation of short-chained proteins via membranes with narrow pores. Thus, different chain lengths for various application fields can be obtained.

Q: How can product loss be minimised when switching between batches?

CD: Pigging technology or Whirlwind technology can be used when pipelines need to be drained between batches. The benefits of thorough cleaning are clear: If different products are separated cleanly, fewer mixed phases occur and this reduces potential losses.

With pigging technology, a device is fed into the pipeline to clear the route. However, it cannot pass through the most common standard fittings. Whirlwind technology, on the other hand, generates an airflow that drains pipelines using a multi-stage process and separates production batches from one another. If required, a Whirlwind can also take care of chemical cleaning and rinsing. It uses a minimum amount of water and cleaning agents and is particularly suitable for rapid switches of product. The other bonus is that different pipe diameters are no obstacle, so a Whirlwind can be used on many system modules simultaneously.

Cleaning is of paramount importance in terms of overall plant efficiency. Depending on the level of production output, either central Cleaning-in-Place (CIP) plants with multiple tanks and chambers or local mobile CIP plants can be installed. It is also possible to extend the system with a Sanitary-in-Place (SIP) process when cleaning has to be followed by sterilisation.

Q: How sustainable is protein processing in terms of resource use and conservation?

CD: While the primary objective of any manufacturer is to utilise all available raw material exhaustively and to produce the maximum output, it is not the only aim. It is vitally important to ensure that resources are used responsibly, so that fresh water and electricity usage are kept as low as possible and wastewater output is minimised.

Protein processing is extremely water-intensive. For this reason, effective water treatment or early reduction of water use are particularly important. Drinking water first needs to be softened in a complex process. After it has been used in processing, however, specialist treatment technology enables a large percentage of the water to be recycled, reducing the amount of organically polluted wastewater that reaches the sewage system. To achieve this, water streams are joined, mixed and subsequently treated with filtering and membrane equipment. Today, up to 80 percent of the water used in protein processing can be recycled in this way.

About Ruland Engineering & Consulting

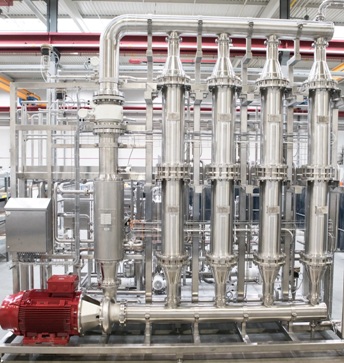

A specialist in liquid process equipment and systems, Ruland Engineering & Consulting develops customised components and innovative solutions for complex requirements. From initial consultancy via planning and realisation to smooth operation and handover, the company provides a comprehensive range of services from a single source. To ensure best results in all cases, the Ruland team works closely with clients to find optimal solutions that are the best fit for individual needs.

Reference:

- Grand View Research, Protein Ingredients Market Size, Share & Trends Analysis Report By Product [Plant (Wheat, Soy Protein Concentrates), Animal (Egg, Milk Protein Concentrates)], By Application, And Segment Forecast, 2018 – 2025. Available at: https://www.grandviewresearch.com/industry-analysis/protein-ingredients-market [Last accessed 2.5.2018].