Spidex Now Offers Factbird Production Monitoring Systems in the UK

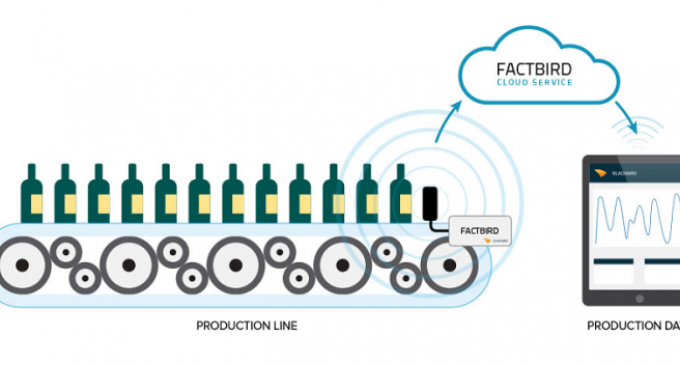

A revolutionary shopfloor datacapture technology is now available in the UK after successful implementations at manufacturing facilities on mainland Europe. The Factbird system was developed by Danish company Blackbird. It comprises a small standalone hardware unit that requires just a power supply and sensor, and which can be installed on a production line in under one hour. The data it collects is delivered in graphical format to a secure cloud server where it can be accessed via PC, tablet or smartphone.

This means that key factory performance measures such as operating speed, units produced, stoppage frequency and downtime causes can be accessed remotely via users’ Factbird login. Factbird’s UK distributor is industrial technology provider Spidex Software. Managing Director Jonathan Starling says: “Factbird is an exciting proposition because you can start monitoring line performance almost immediately. With Factbird, there’s no need for lengthy, expensive implementations. There’s no need to modify machinery or control systems. There’s no IT impact because Factbird sits outside the existing network infrastructure. Factbird is plug-and-play technology, which is what people are accustomed to using now.”

Factbird successes to date include frozen dessert manufacturer Premier Ice, who installed Factbird on a main production line which manufactured a wide variety of popular SKUs. (The high number of product changeovers was the suspected cause of below-par scrap and utilisation figures.)

Production Manager Mette Geisler recalls: “Factbird helped us to analyse the downtime and stoppage causes and as a result the line now shows significantly reduced waste. The data enables us to plan our production process in the most efficient way.”

At the Royal Unibrew beer bottling plant, production personnel were experiencing the issue of a filling line continually running under capacity and with recurring stoppages. Following installation of Factbird, the breakdown root causes were clearly identified and remediated, after which the machine rate was gradually increased back to its optimum level. The result was a substantial percentage increase in bottling line output, achieved in just two weeks.

For more information, or to request a demo of Factbird, please contact Spidex Software Ltd, West Midland House, temple Way, Coleshill, Warwickshire B46 1HH or visit www.spidexsoftware.co.uk.