SonoSteam Technology Tackling Campylobacter in Poultry

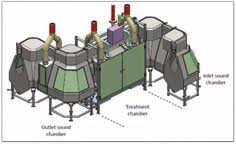

SonoSteam is an innovative technology that is proving highly successful at tackling the pressing problem of Campylobacter in fresh poultry. Developed by Danish company Force Technology, SonoSteam uses a combination of steam and ultrasound to kill microorganisms such as Campylobacter on the skin and internal cavities of chicken. Force Technology has installed SonoSteam at Faccenda Foods and Cargill, two of the UK’s leading poultry processors.

The SonoSteam disinfection system also has wider use within the food industry including meat, fruits, vegetables and dairy products as well as non-food products such as conveyors, food boxes, crates and cutting knives.

Advantages of SonoSteam Technology

SonoSteam technology offers users a number of efficiency, food safety and environmental benefits along with other advantages. “This technology has proved itself capable of working day in and day out in a production environment and is not only cost effective but has been proven effective at reducing Campylobacter in an environmentally friendly way without chemicals, only water and a modest amount of energy,” explains Niels Krebs, Vice President of Force Technology.

He continues: “Delivering the best possible food safety to the customers is an important part of consumer relations. Customers can’t verify the microbiology of a product, so they have to trust the manufacturer. Complaints and products being recalled have severe consequences for the trust between consumer and manufacturer.”

Environmental Impact

Steam and ultrasound have minimum negative impact on the environment and consequently provide a cheaper, green alternative to chemicals. By using force instead of chemicals, SonoSteam will not cause bacteria to become resistant, leading to the formation of ‘superbugs’. Of course, an increased level of food safety improves public health and well being.

Niels Krebs points out: “The potentially increased shelf life caused by SonoSteam reduces food waste, an important problem concerning the environment, hunger, and increasing population. The use of force instead of chemicals makes post-treatment washing unnecessary, which ultimately saves water. Overall the whole process has a minimal impact on our environment.”

Showing Results

The installation of SonoSteam at poultry processing plants in the UK is already showing the effectiveness of the technology at tackling Campylobacter levels in fresh chicken, according to figures from the Food Standards Agency (FSA).

During the October-December 2015 period, which was covered by the most recently published FSA Retail Survey for fresh whole chickens, all poultry sold through Morrisons was SonoSteam processed by Cargill in Hereford. Half of all poultry in ASDA was processed by SonoSteam, as Faccenda Foods only supplies 50% of whole birds sold in the grocery group. The FDA results showed that ASDA dropped from 24% to 10% on birds having a Campylobacter level higher than 1000 cfu/g, while Morrisons decreased from 25% to 5% to achieve the best position in the whole survey.

So what scale of businesses within the poultry industry can benefit from installing SonoSteam technology? The current SonoSteam equipment has been designed for production lines higher than 8,500 birds per hour. “However, many producers with smaller and slower production capacities have been making enquiries for a system running at 6,000 birds/hour,” he says. “Our coming equipment to process cut parts will be more suitable for any scale of business.”

Other Applications

SonoSteam technology has applications beyond the poultry industry and is proving to be a valuable tool for other types of food processors. SonoSteam can be applied on non-food surfaces.

Niels Krebs comments: “We are currently conducting the final testing of food boxes and conveyor belts, and it’s showing great potential. Boxes and conveyor belts constitute a potential risk in cross contamination in clean environments. Microorganisms and their biofilm can build up very quickly on the surfaces, if routine cleaning is inadequate or neglected. Disinfection with certain chemicals can cause selection of dangerous ‘superbugs’ that are able to outlive standard cleaning procedures. At worst case, the bacteria can end up on food products, where it can cause illnesses and even deaths. Listeria is a well-known example of this.”

Non-food surfaces can endure more intense and consequently more efficient treatment, which takes only two seconds for each box to reach a 100% disinfection rate on all surfaces and at lower cost than chemicals.

SonoSteam is also being applied within the health sector. For example, Force Technology is currently working on cleaning boxes that have been used for transporting sterile surgery equipment. Furthermore, the company’s mattress disinfection system is now being used in Danish hospitals.

Fact Box

1 SonoSteam is a minimal process that applies the combined effect of steam and ultrasound for effective and fast disinfection within seconds.

2 The technology is a cost effective and chemical free.

3 Four SonoSteam units are currently installed at two different poultry plants in the UK, processing nearly 4 million birds per week.

4 Ongoing trials have shown more than 80% Campylobacter reduction on birds tested positive for the highest infection levels of higher than 1,000CFU.

5 SonoSteam has many applications and is besides poultry used for disinfection of conveyer belts, food trays and even hospital mattresses.