Primoreels® – ‘The Lidding System of the Future’ – Cost Efficient and Reliable

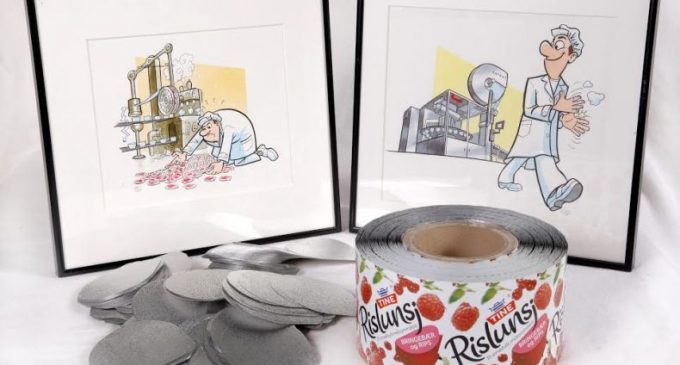

Primoreels has become a well-established and flexible partner for a wide range of manufacturers all around the world – mainly in the dairy industry. Primoreels has invented a lidding system which offers unparalleled advantages to dairy product manufacturers whom traditionally are using ALU/PET die cut lids or roll-stock solutions.

The unique Primoreels® system is already installed in numerous high capacity machines throughout the world, and further development has allowed Primoreels to retro-fit its stand-alone units to existing In-line machines as well as Round table machines, to significantly enhance their efficiency and hygienic security level in production. This comes with a small investment to the existing filling machine, which runs with preformed cups and a die-cut/roll-stock solution. Switching lidding system to a Primoreels solution will be done in a maximum of 4 days – on site – and the existing machine can be of any brand and size.

Each machine unit is tailor-made and has its own dedicated touch-screen panel and controls, thus making them truly independent units without interfering with the current PLC or other on the filling machine. The simple instalment creates the perfect interaction between machine and foil material.

Each machine unit is tailor-made and has its own dedicated touch-screen panel and controls, thus making them truly independent units without interfering with the current PLC or other on the filling machine. The simple instalment creates the perfect interaction between machine and foil material.

Compared to regular die-cut PET and Aluminium lids, Primoreels® PET lids are the new great alternative – cost efficient and with a minimum carbon footprint. Primoreels lids come in thinner materials than normal die-cut lids, and therefore are expected to create savings for customers all around the world.

The reels contains as much as 40,000 lids per reel. Furthermore, it is possible to obtain exceptionally high print quality on the ultra-smooth lid surface. Other obvious benefits include UV-C sterilised lids, which eliminate contamination and increase shelf life.

For further details of Primoreels’ latest innovative lidding products and services visit www.primoreels.com.