KRONEN GmbH Nahrungsmitteltechnik presents state-of-the-art and innovative concepts at Fruit Logistica 2013

Kronen will be exhibiting the latest machinery – for the first time together with 4 cooperative partners (GKS Packaging, NL-Son / JFPT Foodlife, NL-Zwolle / Tenrit-Foodtec, Schloß Holte-Stukenbrock / ZTI Mechatronics, NL-Tuitjenhorn) – based on the motto “Together we are strong!” This joint network offers synergie advantages and appropriate cost saving opportunities to its customers.

Special machine highlights will be:

The completely revised version of the KUJ V cube, strip and slice cutting machine:

perfectly suited for processing vegetables, fruits, fish in equal cubes, stripes or slices in one single step

perfectly suited for processing vegetables, fruits, fish in equal cubes, stripes or slices in one single step- high quality accessories enable neat slicing without damaging the produce

- optimized operational comfort

- flexible placement options (for integration in production line)

- optimized protective hood and product transport

- ergonomic Kronen-design with integrated switch cabinet

- even delicate products such as strawberries, potatoes, tomatoes, peppers or zucchinis can gently be cut

Capacity:

up to 3000 kg / h

The new, big GS 20 belt cutting machine designed and built for the large industrial food processor to cut leafy products, vegetables, herbs:

with 250 mm belt width and perfect product holding until point of cutting

with 250 mm belt width and perfect product holding until point of cutting- to cut whole heads of lettuce and cabbage

- digital in-motion cutting size adjustment from 1 – 50 mm (with 3 blades)

- individually definable programs can be stored and selected by the simple use of control buttons

- optimized knife cover to allow a gentle product handling

- new locking system combined with a new belt cover creates additional safety in the area of the knife

- excellent hygiene qualities: inclined surfaces, stainless steel shaft seals, seamless knife edge

- and many more features

Capacity:

500 – 4000 kg / h (depending on product)

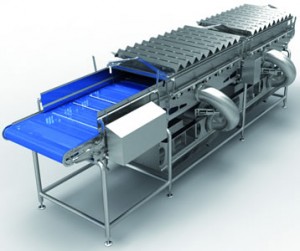

The innovative SDS 5000 suction dry system for salads, fruits, vegetable to achieve a low final moisture:

– longer shelf life due to low final moisture and optimal product handling

– best suitable for processing baby leaf, fresh cut fruit, chopped lettuce, sugar snaps, cauliflower, broccoli florets

– progressive drying process: 2 x 6 steps of blowing and 2 x 6 steps of sucking

– optimal adjustment to the product to be processed via belt speed and frequency controlled blowing system

– optional control via touchscreen to store various recipes

Capacity:

Baby leaf lettuce: 250 – 300 kg / h

Baby leaf lettuce: 250 – 300 kg / h

Iceberg lettuce: 400 – 550 kg / h

Vegetables: 600 – 800 kg / h

On the Kronen stand visitors will also be able to see a wide range of its machines.

As a special attraction, the gourmet chefs Wolfgang Blum and Andreas Eigner will offer various freshly prepared creations to the stand visitors – that are certain to delight their taste buds!

Both chefs have created exquisite meals with seasonal ingredients which already have been published in an own Kronen annual calendar 2013. A great variety of these recipes will be presented live.

Due to the innovative Kronen up-to-date technique the food preparation will become a delicious cooking experience.