Functionalisation and Stabilisation of Ingredients – Innovative Methods Provide Effective Protection

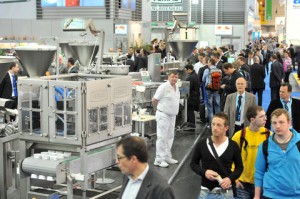

Naturalness has become the decisive buying factor on the supermarket shelves – a trend that is reflected in the growing demand for natural aromas, colouring foodstuffs, health & nutrition ingredients. Their implementation enables food and beverages without ingredients that have to be declared, that can furthermore promise added health benefits. So that the functional ingredients can be integrated into the recipes, they need a protective shell and have to be available as a freely-flowing powder. From 20 to 23 March 2018, Anuga FoodTec in Cologne shows which options there are today for granulating, coating, encapsulating, agglomerating and instantising.

Anuga FoodTec is dedicating an own product segment to food ingredients, the main focus of which will be found on the Boulevard of the trade fair. Additionally the theme is a fixed item on the wide-ranging event and congress programme, which is being organised by the DLG.

Whether to disguise the taste and smell, as protection against moisture, acid or oxidation: When it comes down to customising functional ingredients, fluid bed granulation is one of the state-of-the-art methods. To this end liquids with a high solid content are sprayed onto the fluid bed via a jet system. In interplay with controllable temperatures of between 30 and 130 degrees Celsius, an intensive heat and material exchange enables a uniform drying process without thermal damage. In this way, the nutritional characteristics of aromas or vitamins remain intact within the foodstuffs beyond the minimum shelf life. In addition to colouring agents, plant extracts and aromas, also milk or whey-based protein concentrates are produced. The powders derived excel because of their optimum flow behaviour and easy dosing attributes. There is no need for additional carriers or additives – and the list of ingredients that have to be declared remains short for the product developers. Modern fluid bed systems like those on display at Anuga FoodTec combine drying, granulation and coating in one work process – and what’s more in a small space. The same applies for the ploughshare mixer. They generate a mechanical fluid bed, in which the solids content, grain size and residual moisture can be set precisely.

Whether to disguise the taste and smell, as protection against moisture, acid or oxidation: When it comes down to customising functional ingredients, fluid bed granulation is one of the state-of-the-art methods. To this end liquids with a high solid content are sprayed onto the fluid bed via a jet system. In interplay with controllable temperatures of between 30 and 130 degrees Celsius, an intensive heat and material exchange enables a uniform drying process without thermal damage. In this way, the nutritional characteristics of aromas or vitamins remain intact within the foodstuffs beyond the minimum shelf life. In addition to colouring agents, plant extracts and aromas, also milk or whey-based protein concentrates are produced. The powders derived excel because of their optimum flow behaviour and easy dosing attributes. There is no need for additional carriers or additives – and the list of ingredients that have to be declared remains short for the product developers. Modern fluid bed systems like those on display at Anuga FoodTec combine drying, granulation and coating in one work process – and what’s more in a small space. The same applies for the ploughshare mixer. They generate a mechanical fluid bed, in which the solids content, grain size and residual moisture can be set precisely.

Aromas and vitamins out of the capsule

But the multifunctional systems are capable of doing even more than just producing agglomerates with optimum solubility: They are able to integrate vitamins, minerals and fruit aromas into a stable matrix. A micrometer thin layer comprising of maltodextrin and starch efficiently protects the ingredients that are sensitive to oxidation against outer influences such as light and oxygen. The special feature: The microcapsules don’t release their embedded contents until the food is eaten. A prime example for this is the encapsulation of natrium chloride in a fine shell made of fat. The coated grains of salt form concentrated salt spots in food. The effect: The spots set stronger signals in the tasting receptors and are perceived more intensely. This enables the salt in bakery and frozen products such as pizza to be reduced by up to 20 percent without having an effect on the taste experience.

Engineering expertise meets contract manufacturing

Engineering expertise meets contract manufacturing

The engineering specialists of the exhibiting companies not only plan and set up fluid bed apparatus and entire systems, but together with the food manufacturers develop the entire process through to the tailormade product. The scale-up to the production scale then occurs on-site using a pilot system. The continually increasing capacities in the contract manufacturing section – a service that is offered by several system builders via affiliated production companies – demonstrates that the demand for such functional ingredients is high.

Food ingredients at Anuga FoodTec

Worldwide there is a great deal of movement on the market for food ingredients, where there is a trend towards more naturalness. There is the chance for food and beverage manufacturers to win over new groups of consumers – provided they recognise the signs of the times and pick up on innovative ingredients. Their significance at the Cologne fair grounds will be underlined by the new “Meeting Point – Food Ingredients”, which presents the suppliers of ingredients on a connected presentation display area. The congress and event programme of Anuga FoodTec will also focus on ingredients. Leading experts will grant an insight into the latest developments in the scope of interesting lectures and presentations. In this way, the “Food Ingredients” Forum from Tuesday to Friday will be dedicated to current themes such as clean labels, personalised diets, texture design and enzymes in food production as well as the product reformulation possibilities for exchanging and reducing sugar, salt and fat.