Food For Thought – Reducing Your Energy Costs Through CHP

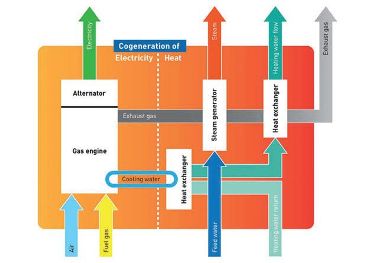

Combined Heat and Power (CHP) is long established within the food industry. Offsetting grid based power supply and producing hot water, steam or chilled water from a natural gas fuelled reciprocating engine has proved very cost effective.

The advantage of CHP are lower operating costs, less reliance on the electricity grid and improved sustainability in terms of carbon usage.

Over the past 3 years wholesale gas and electricity prices have declined, although both have risen in the past 4 months. However, although the wholesale electricity price has reduced, the supply price to consumers has not and has even risen, departing from the usual gas and electricity supply price following each other. The ratio between gas supply price and electricity supply price is often called the spark spread and this too has increased. A greater spark spread makes the installation of a CHP plant a more viable prospect.

The reason for the increase in electricity supply price over the wholesale price is the additional charges for the Green Energy subsidies, and the increases in power distribution costs.

Most sites have a higher electrical power demand than a heat demand which is also often more varied. However, CHP installations assess the site heat requirement to size an installation i.e. the generator is sized so that the heat supply is optimised to the heat demand. This is the most efficient way of using the energy provided in the natural gas fuel and would be counted as good quality CHP. This also maximises the installation sustainability criteria.

Cost Savings

With the increased spark spread, potentially greater cost savings could be made if the CHP is sized to the electrical power demand rather than the heat demand. The electricity pricing is where the greatest cost savings for a company can be made.

With the increased spark spread, potentially greater cost savings could be made if the CHP is sized to the electrical power demand rather than the heat demand. The electricity pricing is where the greatest cost savings for a company can be made.

If an existing CHP is controlled to the heat demand and has extra generation capacity, then consideration should be made to increasing output (and potentially dumping heat) for greater site electrical power supply. This should especially be the case during the peak power demand times between 4pm and 7pm. This period is when the wholesale half hourly power price is the greatest and the where the majority of distribution charges are implemented.

Distribution charges are the Distribution Use of System red band (DUoS) and Transmission Use of System (TNUoS or Triad). In the last quarter of 2016 there were two half hour periods when the spot electricity price hit £1000/MWh.

Edina is a leading supplier, installer and maintenance provider for gas to power solutions, and is the sole distributor for MWM manufactured gas engines in the UK and Ireland.

With over 400MWe installed across the UK, Ireland and Australia, Edina continues to work with the food processing industry, supporting clients to reduce their energy costs, reduce carbon emissions and deliver improved business competitiveness.

If you would like to discuss the benefits and feasibility of CHP within your business, please contact Edina at info@edina.eu or visit www.edina.eu.