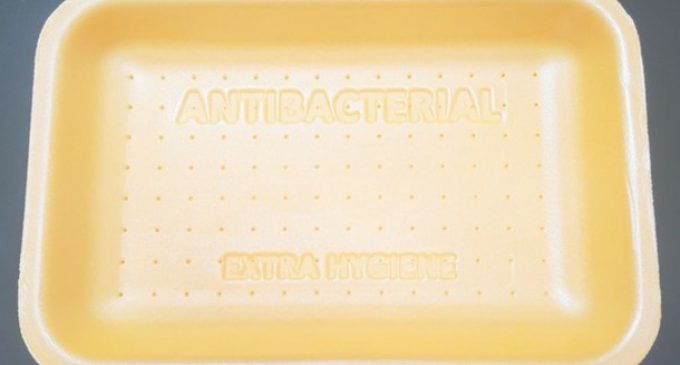

Erze Ambalaj and Parx Plastics partner to create antimicrobial packaging for food

Erze Ambalaj in collaboration with biochemistry developer Parx Plastics has developed a new added value for their product line-up making the packaging antimicrobial.

The technology derived from bio-mimicry and free from biocides is set to reduce the growth of Salmonella, Listeria, E.Coli and Staphylococcus Aureus on the packaging.

The both companies spend the past months researching the best solution for incorporating this technology into the expanding foam packaging in an economical way.

The results are an antibacterial performance, measured according to ISO 22196 by University of Ferrara in Italy, of 92,5% against Listeria, 96% against Salmonella and up to 96,5% against Staphylococcus Aureus. According to the company this leads to 93-97% less bacteria on the surface of the material after 24 hours compared to normal packaging of the same kind.

Specifically the presence of Listeria and Salmonella is an increasing challenge for the market of packaged meats, poultry and fish. With this development a strong tool is in hands to fight the dangers of these bacteria. And the developed protocol makes it possible to implement this technology in a very economical way making the technology available for the entire line of food packaging products.

By reducing the presence of bacteria after the manufacturing of the packaging material, during the transport of the packaging material, during packaging of the food and during the shelf life period of the product the ultimate conditions are created to prevent contamination and to have the best possible shelf life for the product.

The Parx technology is derived from bio-mimicry and it is using one of the most abundant trace elements in the human body to bring forth a change in the materials mechanical/physical property characteristics. The technology is not using biocides; it is able to have an efficient impact on bacterial growth by only a changed material surface property. The trace element used is compliant to the European regulations for plastics that come in contact of food and it is not migrating from the packaging.

Erze Ambalaj A.Ş. is the market leader having 35 years experience in producing world quality food packaging products and insulation sheets with two modern production facilities in Turkey.

Parx Plastics with its headquarters in Rotterdam (The Netherlands) and a laboratory in Bologna (Italy) brings to the market an innovative biocompatible technique to incorporate an up to 99% effective antibacterial/antimicrobial property into plastics.