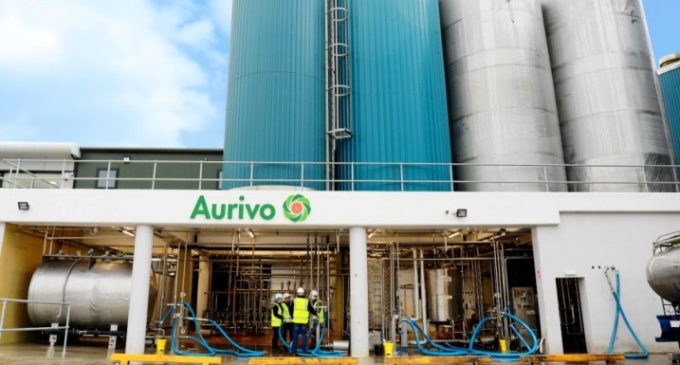

Aurivo Significantly Reduces Fossil Fuel Consumption by Some 80% With GEA Solution

Ireland’s second largest liquid milk processing firm Aurivo has cut carbon dioxide (CO2) emissions at its Killygordon site by 80% and reduced fossil fuel consumption at the facility by 80%, thanks to a multi-million-euro upgrade that has harnessed new liquid processing systems, state-of-the-art energy-saving and refrigeration and heat recovery solutions through heat pumps from GEA. The successful project highlights the benefit of the GEA’s unique SEnS (Sustainable Energy Solutions) concept and has been awarded Excellence in Energy Efficiency Design (EXEED) Certification from the Sustainable Energy Authority of Ireland.

Liquid milk production is a highly competitive business. The Aurivo site in County Donegal annually produces and packages 120 million liters of whole milk, skimmed and low-fat drinking milks, including organic milk, for a range of brands. Milk processing companies operate at very low margins so efficiency is a must. But they also need to stay flexible to meet their customers’ changing demands and production throughput, and are tasked with improving environmental sustainability. To stay competitive, Aurivo was looking to increase efficiency and capacity, as well as reduce carbon footprint. The firm already used a green supplier for its electricity, and so a key goal was to reduce overall energy use, and in particular cut reliance on fossil fuel-fed water boilers.

As a key part of its upgrade program the firm contracted and worked with GEA’s local teams in Ireland to design, configure and install a new refrigeration plant that would replace the existing, outdated and inefficient refrigeration system at the Killygordon facility. As a result of early discussions Aurivo decided to exploit GEA heat pump technology to reclaim and channel excess heat from the new cooling plant to heat water for the milk pasteurization process. This capability would positively impact on energy use, and allow Aurivo to reduce fossil fuel-based heating (boiler), and so also cut carbon emissions.

The GEA and Aurivo utilities teams also worked hand-in-hand with GEA Ireland’s dairy liquid processing specialists, who installed the new, larger 45,000 l/h capacity pasteurizer, together with separation, homogenization and milk standardization equipment that work seamlessly with the upgraded refrigeration and heat pump solutions.

The overall upgrade has increased Aurivo’s hourly milk processing capacity and reduced energy consumption for processing, heating and chilling by about 12%. CO2 emissions have dropped by more than 181,000 kg per year. Importantly, the heat pump technology has dramatically cut Aurivo’s use of fossil fuels for heating the water used for pasteurization.

“The new refrigeration and heat pump solutions provide us with 1200 kW of cooling, and roughly the same in heating capacity,” commented Stephen Carlin, Aurivo’s engineering manager. “The GEA heat pump that collects and recycles what was waste energy from the chiller provides us with the remaining energy needed to take the water up to the pasteurization temperature of a max of 78°C. This has rendered our traditional fuel oil-burning boilers almost redundant for the pasteurization process. In fact, we now only have to turn the boilers on for one hour a week to kick-start each process cycle.” There is also untapped capacity in the heat pump system, Carlin noted. “At present we are only using 50% of the heat pump capacity. If necessary, we could double the amount of hot water produced, and so potentially double our capacity for pasteurization.”

Warm milk skimming GEA separator of type MSI 400 with integrated direct drive and GEA homogenizer of type Ariete NS 3110 H in the background. (Photo: GEA).

As a single source supplier, GEA configurated and installed all refrigeration, heat pump and pasteurizer systems. “We didn’t just provide a heat pump, we optimized the pasteurizer to suit the heat pump application for the Aurivo site,” stated Kenneth Hoffmann, product manager heat pumps at GEA. “All the way through the project we were focused on offering a complete solution, not just individual parts, so that our technologies could help to reduce waste, energy consumption and use of fossil fuels, while increasing capacity and making the Aurivo facility one of the most sustainable dairy plants in Ireland.”

Aurivo is continuing its partnership with GEA through a service level agreement. “We have been hugely impressed with the knowledge of the GEA experts, and it’s really important to us that we will have access to a local service team for the whole GEA equipment,” Carlin pointed out. “There are GEA offices and expert support just a couple of hours away here in Ireland, and we know that we can call on the teams at any time 24/7, to ensure that we don’t have expensive downtime and process stoppages.”

The nuts and bolts of GEA installations at Aurivo

GEA supplied a 45,000 l/h pasteurization system which was pre-assembled, pre-piped and pre-wired on a skid in Germany, before thorough testing and shipping to Aurivo in Ireland. With no on site pipework required, only the product and power lines had to be connected once the system was in situ, so installation and commissioning was really fast.

The pasteurizer is not the only system on the process side of the project that has realized operating benefits. The installed GEA MSI 400 milk separator features an integrated direct drive, which reduces energy consumption compared with conventional drive configurations. The direct drive technology is also comparatively quieter, and saves on space. Control of the entire processing line at the Aurivo site is now fully automated, using the Siemens S7-300 programmable logic controller system.

The combined €2.8 million contracts for the process, refrigeration and heat pump solutions spanned design, configuration, supply and installation of GEA customized refrigeration & heat pump system, and PTC pasteurizer skid, together with MSI 400 separator, GEA standomat MC systems, GEA Ariete homogenizer equipment, and the TP 1500 comfort controller.