Arla Foods Chose to Go ALL-IN

More and more Arla plants are investing in ceramic bearings from CeramicSpeed to reduce damage on production equipment. The benefits of ceramic bearings in the production equipment are nothing short of novelty, and rumor has it that the Danish manufacturer CeramicSpeed, is leading the way. Proof of that is their long-term collaboration with Arla Foods that gets convinced by the benefits of the CeramicSpeed bearings, one dairy plant at a time.

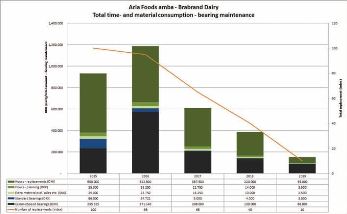

The latest case study comes from their collaboration with Arla Foods Brabrand, a large Danish Arla plant, which was very familiar with the consequences of expensive and unplanned production breakdowns and the significant costs these damages caused. They found the answer in the replacement of all bearings with CeramicSpeed bearings, and on critical equipment combining it with monitoring.

At Arla Robust Processes are Essential

At Arla Foods Brabrand, there is a great focus on constant and robust processes, since the company production is based on orders. This is why it is extremely important to ensure that there are no weak links in the production line. Since the production must not stop until the finished product is obtained, production breakdowns have great financial consequences. Thanks to their longer lifetime, lower energy consumption and the guarantee of a better uptime in production, Arla Foods Brabrand chose bearings manufactured by CeramicSpeed to save significant costs within a few years.

At Arla Foods Brabrand, there is a great focus on constant and robust processes, since the company production is based on orders. This is why it is extremely important to ensure that there are no weak links in the production line. Since the production must not stop until the finished product is obtained, production breakdowns have great financial consequences. Thanks to their longer lifetime, lower energy consumption and the guarantee of a better uptime in production, Arla Foods Brabrand chose bearings manufactured by CeramicSpeed to save significant costs within a few years.

Bearings and Monitoring as Part of Production Efficiency

“Trying to fix immediate problems is expensive and impossible to plan ahead,” says Michael Helm from Arla Foods Brabrand. This is why, it is essential for him, to find a model that secures better uptime in production. “In collaboration with ME Aarhus and CeramicSpeed, we have found a solution. We have started the process of replacing everything with CeramicSpeed bearings in all of our machinery, implementing monitoring on critical machines at the same time. Through this, we can take action before the damage actually occurs, that is before the following financial consequences appear. In our experience, the maintenance cycle is improved with CeramicSpeed bearings, thanks to the bearing lifetime that is much longer than standard steel bearings. To us, this has resulted into a better use of resources in our maintenance department, and fewer costs for the maintenance of production equipment. Now, the need for maintenance is considerably smaller and we can act before the damage occurs.”

At Arla Foods Brabrand, CeramicSpeed has seen the same pattern as with other industrial companies. The extra cost you pay for CeramicSpeed bearings has very little importance compared to the frequent breakdowns and related costs. For this reason, the dairy has chosen to go ALL-IN, which means making all of their equipment more efficient by replacing their bearings with CeramicSpeed bearings and combine the replacement process with monitoring in critical areas.

“Over time, we expect less breakdowns caused by the bearings. This is, without a doubt, based on the high-quality of CeramicSpeed balls and the other components in the bearings. This is not a standard bearing, but a bearing in which, the focus is on the machine in which it will operate. Even though the bearings are a bigger investment, the price is not decisive. The saved costs for other machine parts that also typically break in connection with breakdowns and the loss of production capacity, result in a smaller total expense. There is actually a great deal of money to be saved,” says Michael Helm.