Anson boosts production with new cooling kit

UK-based Anson Packaging has invested in a new cooling system by Aqua Cooling to help streamline its production process at its manufacturing plant in Cambridgeshire.

UK-based Anson Packaging has invested in a new cooling system by Aqua Cooling to help streamline its production process at its manufacturing plant in Cambridgeshire.

Part of Danish packaging manufacturer Faerch Plast Group, Anson Packaging provides thermoforming to the food industry in the UK.

Following the installation of the new system, Faerch Plast will use glycol-free and magnetically-driven centrifugal compressor chillers at its sites worldwide.

A Faerch Plast representative said: “Thanks to the Turbocor technology, we can now achieve maximum efficiency at a reduced load.

“We no longer have excess machinery on standby in case of servicing or faults, which is something that has always seemed a waste of investment to me.”

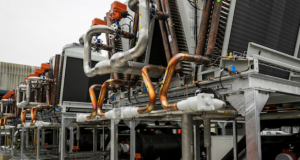

The new chiller system installed at Anson Packaging’s site includes two 700kW and two 800kW air-cooled, thermosyphon, free-cooling Turbocor units using R134a refrigerant.

The system design spreads the cooling load, ensuring optimum cooling and ultra-high efficiency levels at all times. It also has built-in redundancy to ensure that the cooling process continues in cases of malfunction.

Furthermore, Aqua Cooling’s system enables free cooling at a higher ambient temperature than normal.

Compared to traditional scroll compressors that offer integrated free cooling, the new Turbocor solution is 60% more efficient in terms of overall electrical operation costs.

The Turbocor technology works with variable flow, allowing it to operate with a primary pump set, while typical scroll compressors require both a fixed flow and a secondary pump set.

Anson Packaging’s new system has saved a total of 94kw of fixed pump and fan motor energy after the installation.

Anson Packaging Ltd. designs and manufactures thermoforming packaging products to the food industry.