Au2mate Delivers the Fully Integrated Factory Automation System For the Arla Foods Ingredients Hydrolysates Factory

By Klaus Dam, Managing Director of Au2mate A/S

This article gives an overview of the design and implementation process for the highly advanced factory automation system at the Arla Foods Ingredients Hydrolysates factory opened in June 2016.

The project has been implemented in close cooperation with AFI as the end user and Process Engineering as the main engineering contractor and with Au2mate as the supplier of the factory control system.

The Hydrolysates plant is complex both in terms of processes and applied automation technology and at the same time the performance requirements are set very high; this includes user friendliness, process optimization, waste, energy consumption, detergents and plant uptime.

The plant automation solution is based upon the latest yet proven technologies and equipment from leading manufacturers, ensuring the investment and future development of the plant.

The engineering standards applied as the basis for the solution are leading international standards ensuring the quality today as well as flexibility with regard to future support and development. The project is fully documented accordingly.

The software solution is designed according to S88/S95 which forms a robust platform supporting superior management of the dairy inclusive of fully integrated manufacturing order execution.

Extended use of well proven software modules in accordance with Arla Foods standards, guidelines and best practices ensures straightforward future development, extensions and maintenance.

The solution designed and implemented at the AFI Hydrolysates factory is embedding the joint Au2mate expertise and good automation practice gained from conducting major automation projects over more than 3 decades.

To future proof the plant it is most important to recognise that the plant automation system is designed in a flexible manner in order to facilitate that the process can be optimised concurrently during the life time of the plant aligned with changes in production requirements, process requirements and on-going changing and upgrading of production standards.

From an automation perspective the key to achieve this is to design the hardware as well as the software in a modular, standardised and well documented way. And further that the applied technology for the plant automation system is transferred to the operational organisation of the AFI Hydrolysates factory.

Below in this article there is a more detailed description of the design and functionality of the control system as well as the implementation and project management of the project. Please refer to below photo showing a part of the process area.

Design and Functionality of the AFI Hydrolysates Factory Control System

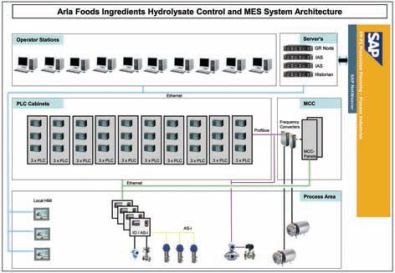

The plant is equipped with a comprehensive automation system comprising I/O, PLC, SCADA, MES as well as communication networks.

Operation of the plant takes place from 10 pcs. Wonderware InTouch operator stations located in the central control room as well as in the field for operation and monitoring of the plant.

The control system is based upon 20 pcs Siemens S7-414 PLCs for the process. Interface to the plant items takes place via ET200 modules located in I/O boxes in the plant process area. The interface boxes are connected to the PLCs via Profinet. Interface to the MCC takes place via ET200 modules located in the MCC panel connected to the PLCs via Profibus. Interface to selected process instruments also takes place via Profibus.

The server part of the control system is based on Wonderware System Platform and includes 4 servers running a Historian server and a redundant pair of Application Servers. For more information please refer to the below figure 1 showing the Automation Architecture.

The software part of the system is designed according to Arla Foods standards for PLC, HMI, Data collection, Recipe management, OEE and reporting. The control system structure follows the basic principles in the ISA S88 Batch Model. The MES application is S95 structured and designed according the latest international standards.

The plant is fully automatic and requires a minimum of operator interaction and the automatic sequences will control the process under full control system monitoring and supervision.

The PLC software is developed for control and monitoring of the individual plant units forming the entire Hydrolysates process. The software comprises modules for automatic control, regulation and monitoring of the plant as well as handling of operator interaction. The software is structured according to S88 and extensively tested and simulated to obtain optimal commissioning of the plant.

The software for automatic control of the process energises actuators, valves and pumps in a predetermined sequence hereby initiating the individual processes. The key components and process parameters are carefully monitored during process operation, including e.g. monitoring of states, pressures and temperatures. Alarm handling and logging includes alarm state, date and time. For quality purposes, process events are logged in a database inclusive of e.g. date, time, material, recipe number and production order.

The application software for the HMI/SCADA system is based on Arla Foods standards. The software is developed as user friendly graphics based operator pictures ensuring an efficient operator dialogue during operation as well as monitoring of the plant. Please refer to photo below showing the central control room.

The MES solution is based upon the platforms from SAP, Microsoft, Wonderware and Arla Foods, providing a fully documented and open standard platform, safeguarding the investment and ensuring straightforward future development of the plant. The SQL database is designed according to S95 forming the backbone for the required MES applications and reports.

The plant is running recipe controlled production based upon the use of Arla Foods recipe system RMS as well as integration with SAP production orders.

The collection of production data and associated reporting is based on the Arla Foods modules for data collection and reporting via MII.

The OEE functionality is based on the Arla Foods standard. The plant status is registered continuously e.g. machine error, line error, etc. and OEE reports are implemented via MII.

Implementation and Project Management of the AFI Hydrolysates Project

The project was generally executed according to Au2mate QA manual complying with leading international standards and methodologies inclusive of development of test sheets for quality assurance.

The planning and coordination of the project was performed by an appointed project manager in close cooperation with the AFI organisation and the process contractors. The project manager also coordinated and organised the work in the dedicated Au2mate project group.

The software programming of the AFI Hydrolysates plant control and MES system was carried out on the basis of Functional Design Specifications (FDS) prepared by Au2mate and approved by the process contractors. The FDSs describe all sequences and Unit operations in detail.

The detailed software Factory Acceptance Test (FAT) was carried out on the Au2mate premises prior to on-site tests. The FAT is introduced in order to ensure that as regards control, the plant operates according to the program description (FDS). The test was conducted in corporation with AFI, their representatives and the process contractors.

Training of the AFI staff was done in parallel with the project execution, in order to develop the skills required to operate, run and execute maintenance of the plant independently of external support.

A simulation concept of the plant was created as part of the project. The concept was applied as a helping tool for the FAT as well as a training tool for training of plant operators and maintenance staff.

A simulation concept of the plant was created as part of the project. The concept was applied as a helping tool for the FAT as well as a training tool for training of plant operators and maintenance staff.

Key Project Learning Points

It has been a pleasure for Au2mate to act as a proactive automation supplier in the delivery of the control system for the AFI Hydrolysates factory. The project was successfully delivered on target for time, budget as well as quality.

From our perspective the goals were achieved due to clear project targets and project management by AFI, sufficient knowledgeable resources allocated to the project and excellent teamwork during the whole duration of the project between AFI and the vendors involved in the project.