ACMA and the machines for edible products: different fields, same commitment

ACMA, a company of Coesia group, is an entity specialized in the design, manufacture and commercialization of automatic machines for packaging of daily consumer goods. In the last months ACMA has reinforced its commitment in all these fields, where it is a protagonist, among which the

ACMA, a company of Coesia group, is an entity specialized in the design, manufacture and commercialization of automatic machines for packaging of daily consumer goods. In the last months ACMA has reinforced its commitment in all these fields, where it is a protagonist, among which the

one of tea coffee and confectionery by presenting new models and taking part to exhibition events.

When tradition goes hand-in-hand with change Year 2016 opened under the banner of a great dynamism for the Bolognese company, since it is always dedicated to the research of cutting edge solutions and attentive to the market evolutions. ACMA, on one side reconfirms its commitment to improve its machine technology, aiming – besides the performance – at aspects like energetic efficiency and sustainability; on the other hand it works to increase its solution portfolio so as to fully meet with the various requirements of the markets where it operates.

Concerning the field of the liquid and solid edible products, characterized by several and very different sectors, ACMA is present with proposals for the confectionery, for tea and coffee. At the beginning of the year, the company took part in ProSweets in Cologne, Germany, where it presented in world premiere the new Wm600 CC for the Confectionery sector. In the month of May ACMA was present at the Tea&Coffee World Cup forum in Krakow, Poland, reaffirming its position in the tea field.

Moreover, it continues the commitment in the coffee and soluble in capsule, to which the Bolognese company offers now a solution portfolio able to cover different phases of the packaging. Whatever the reference field, ACMA works to be more and more close to the customer, standing beside him from the line design to the after-sales phases, thanks also to technologies like ARA (Advanced Remote Assistance), a tool to control in remote the machine functionality by the specialized ACMA engineers that permits a “virtual” juxtaposition during the assistance phases.

Confectionery – a new medium speed machine to meet the sector needs in the best possible way

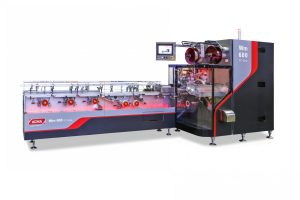

ACMA has an experience unique in the world in the specific field of packaging of candies, sweets and bakery products, where since over ninety years ago, it started its activities and now is one of the most important players on the market. At the beginning of the year it presented in world premiere the Wm60o CC, an alternate movement machine for the multi-style packaging of products like chocolates,

ACMA has an experience unique in the world in the specific field of packaging of candies, sweets and bakery products, where since over ninety years ago, it started its activities and now is one of the most important players on the market. At the beginning of the year it presented in world premiere the Wm60o CC, an alternate movement machine for the multi-style packaging of products like chocolates,

taffies and plane-base candies.

It is a unit designed to meet the specific demands of the markets that require medium speed solutions (the machine can reach 600 strokes per minute) characterized by high flexibility and easy use. In fact, the Wm600 CC permits realizing various shapes, like bunch, double ribbon, cherry cordials, wallet and fantasy, ensuring a perfect package also in case of products with inner and outer wraps with different dimensions.

The compact layout enables it to integrate perfectly inside various production environments, while the balconytype shape and the use of brushless motors make easier the operating, maintenance, and cleaning activities.

The offer is completed by the possibility to work with all main wrapping materials and the standard equipment of the ARA system. The Confectionery portfolio is enriched by solutions that go from the M888, a multi-style high-speed machine to the flowpackers of the SP series, up to a wide range of horizontal packers.

Tea: T2, T4 and T10, three winning solutions

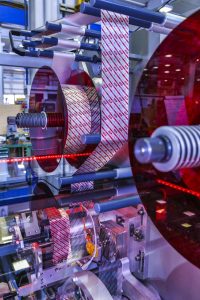

ACMA, with its Tecnomeccanica brand, continues to point to the development of solutions for packaging the tea bags, with a portfolio complete of machines able to meet the requirements of the main word producers. The recent participation to the Tea&Coffee World Cup forum intended to reconfirm the commitment of the Bolognese reality in one of the leading sectors of its activities.

ACMA’s offer includes the T4 Modula, the solution for the packaging in double-chamber bags that was recently technologically upgraded to increase the performances and is now able to reach a speed of 300 strokes per minute. The characteristics that made it a unique solution on the market: specifically, the capacity to make doublechamber bags , without using glue and staple putting the tied tag on the front part of the package to the benefit of the esthetic and practical use.

ACMA’s offer includes the T4 Modula, the solution for the packaging in double-chamber bags that was recently technologically upgraded to increase the performances and is now able to reach a speed of 300 strokes per minute. The characteristics that made it a unique solution on the market: specifically, the capacity to make doublechamber bags , without using glue and staple putting the tied tag on the front part of the package to the benefit of the esthetic and practical use.

Moreover, T4 is equipped with advanced motors with energy recycle as completion of a project born keeping into maximum consideration the aspects tied to the environmental sustainability and to saving. Finally, T4 is an extremely flexible and modular machine, able to be configured to cover different packaging phases. In fact, besides packing the tea leaf, the machine can include units to package the bags inside cardboard boxes, having different formats and types.

Moreover, the portfolio includes the T10 Continua, top of the line, also dedicated to the packaging of double chamber bags, characterized by continuous movements able to produce 500 products per minute. To meet with the requirements of packing in chamber, there is the T2, one of the machines more appreciated on the market that can be configured in different variations, from “Prima” – the base version – to “Full Leaf” for packaging the entire tea leaf up to the “High Speed”, unit able to produce up to

320 bags per minute , that could offer to the top players of the sector, a remarkable reduction of the labor costs and increase of the production efficiency.

Coffee and soluble: from the machine for packing in capsules to the secondary packaging

The commitment in the coffee sector continues, the last field that ACMA entered in 2013 with the presentation of the Qi 350 model, dedicated to the filling in capsule and characterized by technologically advanced solutions, among which the design of the dispenser located on independent stations (that guarantees the maximum precision in the weight check in the filling phase) and the presetting for the vacuum directly on the machine, to increase the product shelf life.

The commitment in the coffee sector continues, the last field that ACMA entered in 2013 with the presentation of the Qi 350 model, dedicated to the filling in capsule and characterized by technologically advanced solutions, among which the design of the dispenser located on independent stations (that guarantees the maximum precision in the weight check in the filling phase) and the presetting for the vacuum directly on the machine, to increase the product shelf life.

During the last three years the company has widened the solution range: the Qi family has in fact enlarged with the arrival of the 500 module, that shares with the 350 the general setup, increasing the production performances and of Qi 800, that with respect to Qi 350 and 500 is characterized by a more traditional line layout. The Qi 800 and is considered as a solution able to combine excellent production performances with high reliability and strength.

The last arrival in the family of solutions for coffee and soluble products is Miniwrap, “green” and “cost saving” machine for packing the capsules in flowpack: ideal solution for the completion of production lines. Developed according to principles aimed at reducing the material consumption and limit the costs, Miniwrap, with respect to the solutions traditionally in use on the market, permits saving 30% of the wrapping material and 50% on the packing volume. This translates in an optimization of all logistic expenses which are downstream the production chain: from the transport costs to the storing ones, up to the product placement in the sale points.